Gear pumps are positive displacement pumps that operate by trapping fluid between the teeth of a rotating gear and the pump casing. Understanding the principles behind gear pump operation is critical to effectively utilizing these pumps in a variety of applications.

At the heart of a gear pump are two meshing gears - a driving gear (usually the input shaft) and a driven gear. These gears rotate within the pump casing, creating a sealed chamber between the gear teeth and the pump casing wall. As the gear rotates, fluid is drawn into the chamber on the suction side of the pump and discharged from the chamber on the discharge side. This action causes fluid to flow continuously through the pump.

1.Understanding Gear Pump Operation

2.Initial Priming and Lubrication

3.Step-by-Step Guide to Starting a Gear Pump

1.Understanding Gear Pump Operation

A key aspect of gear pump operation is the positive displacement principle. Unlike centrifugal pumps, which rely on centrifugal force to move fluid, gear pumps displace a fixed volume of fluid with each revolution of the gears. This makes gear pumps ideal for applications requiring precise flow and pressure.

The efficiency of a gear pump depends on factors such as gear design, clearance between the gear and housing, and the viscosity of the pumped fluid. Proper selection and maintenance of gear pumps is critical to ensuring optimal performance and service life.

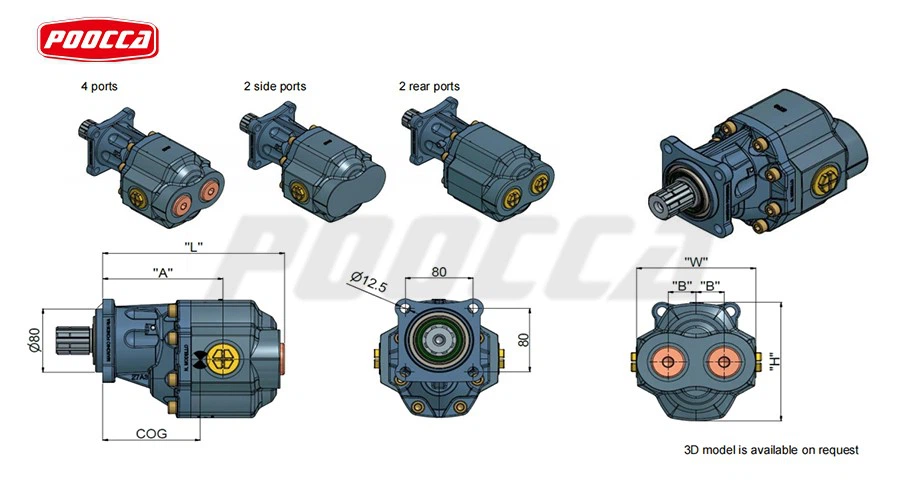

Gear pumps operate on the positive displacement principle, utilizing meshing gears to capture fluid and move it through a sealed chamber. Gear pump materials include cast iron gear pump, aluminum gear pump and other high-quality materials

2.Initial Priming and Lubrication

The working principle of a gear pump is based on two intermeshing gears that rotate in a closed chamber to transport fluid. As the gears turn, the tooth grooves of one gear combine with the tooth grooves of the other to form a series of sealed chambers. As the gears rotate, these chambers draw fluid in on the suction end and force it out on the discharge end. This process requires very precise clearances between gears and chambers, and between gears, to reduce leakage and increase efficiency.

When a gear pump is first started or restarted after a long period of disuse, sufficient lubrication may not be present in the system. Therefore, initial priming and lubrication is crucial in order to protect gear surfaces from wear and avoid early failure.

Initial priming and lubrication of a gear pump is key to ensuring smooth startup and operation. Proper start-up procedures not only protect the gear pump from damage, but also increase the efficiency and reliability of the entire hydraulic system. Therefore, operators and maintenance engineers should strictly follow the pre-start preparation steps to ensure optimal performance of the gear pump.

Poocca gear pumps are sold under brands such as casappa gear pump, salami hydraulic pump, rexroth gear pump and other brands. Poocca hydraulic pump manufacturer is a one-stop enterprise that completes production, sales and maintenance. The quality is guaranteed, the price is favorable, and the delivery time is There is speed, welcome to send your requirements, we will reply to you as soon as possible.

3.Step-by-Step Guide to Starting a Gear Pump

Starting a gear pump requires careful preparation and execution to ensure smooth and efficient operation. Here is a comprehensive step-by-step guide to help you start your gear pump effectively:

Step 1: Check and Prepare

Before starting the gear pump, perform a visual inspection to ensure that the pump and surrounding area are clear of any obstructions or hazards. Check hydraulic pump internals for signs of leakage, damage or wear.

Next, make sure the pump is properly connected to the power source and that all electrical connections are secure. If the pump is driven by an engine or motor, make sure the power source is in good working order and properly calibrated.

Step 2: Start the pump (if necessary)

In some cases, a mini gear pump may need to be primed to move fluid efficiently. Priming involves filling the pump chamber with liquid to eliminate any air pockets and create a vacuum for efficient pumping.

To prime the pump, locate the priming port or valve on the pump casing. Open the filling port and pour the appropriate type and amount of liquid into the pump chamber until it is filled to the desired level.

Once the pump chamber is properly primed, securely close the prime port or valve to prevent fluid leakage.

Step 3: Lubrication

Proper lubrication is critical to the smooth operation and longevity of your gear pump. Before starting the pump, make sure all lubrication points are properly lubricated or oiled according to the manufacturer's instructions.

Check the lubrication system to make sure it is operating properly and that there are no leaks or blockages in the lubrication lines.

Step 4: Turn on the computer

After completing the inspection, start-up (if necessary) and lubrication steps, it is time to turn on power to the gear pump.

If the pump is electric, turn on the power and start the pump motor according to the manufacturer's instructions. If the pump is engine driven, start the engine and engage the pump drive mechanism.

Step 5: Monitor operations

Once the pump is powered on, carefully monitor its operation to ensure everything is running smoothly. Watch for any unusual noises, vibrations, or leaks that may indicate potential problems with the pump.

Check the pressure and flow of the pumped fluid using appropriate gauges or instruments to ensure they are within the required ranges.

Step 6: Tuning and Troubleshooting

If any problems occur during pump startup, such as unusual noises or performance fluctuations, take immediate steps to diagnose and correct the problem.

Refer to the pump operating manual or consult a qualified technician for guidance on troubleshooting and making necessary adjustments.

Step 7: Close the program

Once a gear pump has been successfully started and operating as expected, proper shutdown procedures must be followed when no longer needed.

Gradually reduce the speed or power input of the pump to bring it to a gradual stop and prevent damage from sudden stops.

If the pump requires maintenance or repair, follow the manufacturer's recommendations for shutdown procedures and safety precautions.

Poocca Hydraulics Manufacturers reminds you that starting a gear oil pump requires attention to detail, proper preparation and following safety procedures. By following the step-by-step guide above, you can ensure your gear pump starts smoothly and efficiently, resulting in reliable performance in a variety of applications.