Introduction

Hydraulic motors lie at the heart of countless industrial and mobile-equipment systems, converting the energy of pressurised fluid into reliable mechanical rotation. Whether driving a winch on a marine vessel, propelling a tracked vehicle, or powering a pump in a manufacturing cell, these motors take on rigorous demands and must perform flawlessly.

But even the finest motor will be compromised if installation is sloppy, or maintenance neglected. For manufacturers, suppliers and end-users alike, correct installation and ongoing care are the foundation of operational reliability, service life extension and minimised total cost of ownership.

In this article, you'll gain a structured, trustworthy overview of what it takes to install a hydraulic motor properly and keep it performing at peak for years. The goal: to empower technicians, engineers and buyers with actionable insight - helping ensure that the motor you select, mount, connect and service lives up to its promise.

Overview of Hydraulic Motors

What Is a Hydraulic Motor?

A hydraulic motor is a mechanical device that transforms hydraulic energy (pressurised fluid) into rotary mechanical motion (torque and shaft rotation). In simple terms, it reverses the function of a hydraulic pump: whereas a pump converts mechanical input into fluid flow and pressure, a motor uses fluid flow + pressure to produce mechanical output.

Key Performance Parameters

When selecting or evaluating hydraulic motors, a number of parameters must be considered:

- Displacement: The volume of fluid required for one revolution of the output shaft, often expressed in cm³/rev or in³/rev.

- Torque: The rotational force generated at the output shaft, typically a function of system pressure and the motor's displacement.

- Speed: The rotational speed (rpm) of the motor shaft, determined by input flow and displacement.

- Continuous & intermittent pressure ratings: Particularly for high‐performance motors, continuous working pressure vs. peak pressures must be distinguished.

- Duty cycle / ambient conditions: For mobile vs stationery use; vibration, shock loads, temperature extremes all factor into motor selection and lifecycle.

Common Types of Hydraulic Motors & Their Applications

Gear Motors

These consist of meshing gears (idler + driven) that convert fluid flow into shaft rotation. They are relatively simple in design and common for moderate torque/speed applications.

Applications: mobile equipment (light duty), conveyors, mixers.

Pros/Cons: Robust, cost‐effective; but less efficient at high pressures or very low speeds compared to piston types.

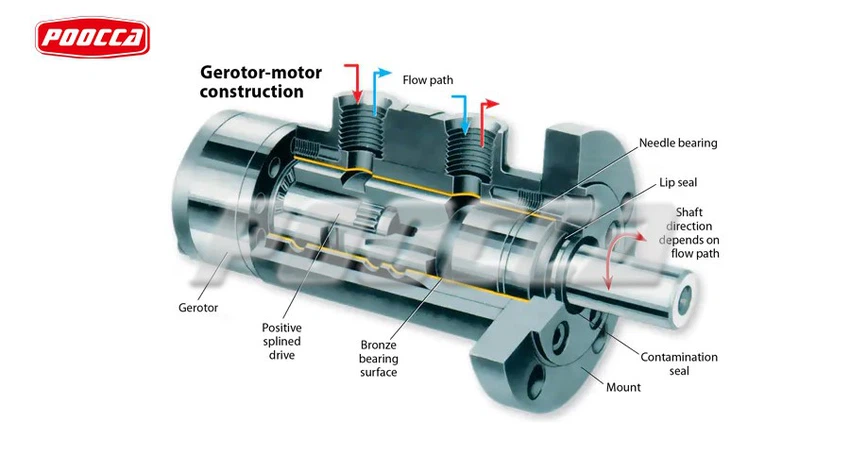

Vane Motors

These use sliding vanes in an eccentric housing to generate rotation. They offer a balance of efficiency and cost.

Applications: screw conveyors, industrial machinery, moderate duty mobile equipment.

Pros/Cons: Better than gear in leakage control; but not as high‐torque or high‐pressure capable as piston types.

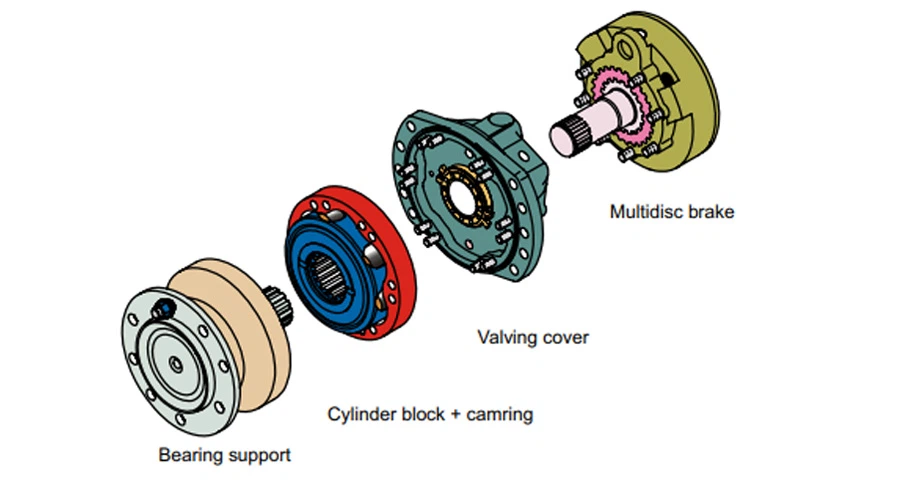

Piston Motors

The highest performance category, including both axial‐piston and radial‐piston designs.

Axial piston motors: pistons arranged parallel to the shaft, often variable displacement.

Radial piston motors: pistons arranged radially around the shaft-excellent for high torque, low speed.

Applications: heavy equipment, marine drives, winches, low‐speed/high‐torque drives.

Pros/Cons: Superior performance, longevity, and adaptability-but higher cost and more complex installation/maintenance.

Classification by Speed & Torque

Another useful view: hydraulic motors may be classified as "High Speed/Low Torque" (HSLT) or "Low Speed/High Torque" (LSHT).

HSLT: fast rotation, lighter loads.

LSHT: slower rotation, heavy loads, precise control.

Installation of Hydraulic Motors

Pre-Installation Checks

Confirm that the selected motor model matches the system requirements-check displacement, rated speed, torque, continuous/intermittent pressure ratings and ambient conditions. Industry guides emphasise: "Confirm that hydraulic specifications are within motor specifications."

Inspect the motor and the related components for shipping damage, contamination (dust, metal chips), rust or coatings on mounting surfaces. Some manufacturers note: "The support surfaces must be clean (free of paint, grease, oxidation, etc.) in order for it to be properly mounted."

Ensure the hydraulic system is ready-clean fluid, correct viscosity, filtration in place, system lines flushed. Clean system before installation to prevent contamination damage.

Ensure all tools, gaskets/seals, mounting bolts, alignment equipment, lifting devices are prepared. Lock out and depressurise the system before installation begins.

Mechanical Mounting & Alignment

Mount the motor on a rigid, flat, vibration-minimised surface. Many motor failures trace back to flexing or misalignment during operation. For example: Manufacturer guidance states that mounting surfaces must be free of paint, properly cleaned and support the motor securely.

Shaft coupling must be correct: choose a coupling type appropriate for your application (rigid vs flexible), verify tolerances, radial/axial loads, side-loads minimisation. The user manual from Parker warns: if axial and/or radial force will act on the shaft, the user must consult the manufacturer.

Use a torque wrench for bolt tightening as per specification. Re-use of old bolts, improper torque or greasing/degreasing can compromise integrity. E.g., an installation guide notes: "Bolts must be new … Use a torque wrench to comply with the predefined tightening torques."

Avoid side-loads on the shaft, ensure the mounting bracket or torque arm is designed to absorb counter-torque without stressing the motor bearings.

Hydraulic Connections (Inlet, Outlet, Case/Drain)

Identify ports correctly: inlet vs outlet vs case-drain if present. Incorrect porting reduces performance or causes failure. The guide from Hidraoil emphasises correct hose/pipe diameter for flow and avoiding kinks.

Hose/pipe sizing: ensure inner diameter, wall thickness, fitting ratings match system requirements. Avoid sharp bends, loops, or contact with hot or vibrating parts. Flexible hoses are preferred in high vibration areas.

Case or housing drain: if the motor includes a case drain port, ensure it is connected and free-flowing so that internal housing pressure doesn't build up. One installation guide states: "The drainage of the hydraulic motors' casings must be sized adequately to limit the casing pressure in conformance with the specifications."

Route hoses carefully: support them to avoid fatigue, ensure length and routing allow for machine movement without stressing fittings.

Clean port plugs and covers: if the motor was shipped with protective plugs, remove them, inspect the ports for debris, then connect lines making sure all seals are intact.

Filtration, Fluid & System Preparation

Ensure hydraulic fluid meets the viscosity, cleanliness and specification required by the motor manufacturer and system designer. Too many systems fail because of bad fluid. Several sources highlight that cleanliness is essential.

Pre-filtration and flushing: before putting the motor into full operation, flush the system to remove residual debris from plumbing, welding, hose routing. The manual from Hidraoil states: "The oil used in the hydraulic system must be completely clean of impurities before installing the hydraulic motor. Also clean the internal walls of the hydraulic reservoir."

Install or examine filters (inlet, return, case drain) and monitoring devices.

Purge air: ensure the system and the motor case are free from air; air in the system leads to cavitation, reduced efficiency and heat.

Initial Startup & Testing

After installation, before full load, run the motor unloaded or under light load to verify mounting, alignment, hydraulic connections, fluid flow and motor behaviour. One manual suggests: "Run the motor without load at minimum speed and with zero (or minimum) pressure for several minutes first, then gradually increase rpm and pressure."

Monitor for vibration, abnormal noise, temperature rise, leaks at fittings, correct rotation direction, correct speed vs flow, and evacuation of air.

Only once the motor behaviours correctly under light conditions should you gradually introduce normal load.

Document the initial hours of operation (say 50-100 hours) and schedule inspection after that to catch early signs of issues.

Provide reference to the user (customer) that any significant deviation in performance in the early stage may indicate installation error and should be corrected before full production use.

Maintenance of Hydraulic Motors

Preventive Maintenance Schedule

A consistent and well-structured maintenance schedule helps avoid unplanned downtime, reduces repair costs, and extends motor life. Below are typical intervals and tasks derived from industry best practice.

Daily / Before Each Shift

Check hydraulic fluid level; top up if required.

Inspect for external leaks, unusual noises or vibrations.

Ensure motor and surrounding area are clean (especially around breathers, reservoir caps) to avoid contamination ingress.

Weekly / Monthly

Check filter indicators and inspect filters for clogging, replace if necessary.

Inspect hoses, connections and fittings for wear, cracking, bulging, signs of fatigue.

Monitor fluid temperature and operation conditions vs. specifications.

Quarterly / Annually

Take fluid samples and perform cleanliness/contamination analysis (particle count, water content, viscosity).

Inspect motor alignment, shaft bearings, mounting bolts' torque and condition of coupling.

Replace seals, O-rings, gaskets that have worn or started leaking.

Key Focus Areas

When maintaining hydraulic motors, there are four major areas that deliver the most impact: fluid & contamination, temperature, alignment/load, and connections/seals.

Fluid Cleanliness & Quality

Contamination (particles, water, air) is consistently cited as a leading cause of motor failure.

Use filters rated for the appropriate micron size, and monitor bypass / clog indicators.

Protect breathers and reservoir fills; use desiccant or vent filters if environment is harsh (moisture/dust).

Regular fluid analysis to capture trends and catch contamination early.

Temperature & Operating Conditions

Running too hot or too cold is detrimental:

Overheating softens seals, reduces fluid viscosity, speeds wear.

Low fluid temperature (or too high viscosity) reduces lubrication, increases losses.

Ensure cooling, proper relief valve settings, correct fluid type/viscosity.

Alignment, Load & Mechanical Integrity

Misalignment or side-loads on the shaft/bearings significantly reduce service life.

Avoid overload beyond the motor's rated torque/speed; this causes excessive heat, wear.

Regularly check mount bolts, coupling condition, vibration levels.

Connections, Seals & External Condition

Leaking seals, loose fittings or damaged hoses invite contamination and reduce efficiency.

External cleanliness (no dust build-up around vents or breathers) helps prevent ingress and overheating.

Troubleshooting Common Issues

Here are some scenarios that are frequently seen in the field-and what maintenance teams should check when they occur.

| Issue | Possible Causes | Recommended Action |

|---|---|---|

| Reduced speed or torque | Internal wear, contamination, incorrect pressure/flow | Check fluid cleanliness, perform flow/pressure test, inspect internals |

| Excessive noise / vibration | Bearing failure, misalignment, cavitation or air in fluid | Check alignment, mounting, purge air, inspect condition of bearings |

| Overheating | Excess load, fluid viscosity too low/high, cooling failure | Check load vs rating, fluid temperature/viscosity, cooling system |

| External leaks | Worn seals, loose fittings, cracked housing | Replace seals, tighten fittings, inspect housing for cracks |

| Unexpected shutdown or erratic behaviour | Contamination, sensor failure, air ingress | Conduct fluid analysis, inspect sensors, purge air |

When documenting such issues, reference reliability logs, hours of operation, environment conditions-this helps in identifying patterns and improvement areas.

Overhaul & Repair Considerations

Even with the best maintenance, motors will eventually reach a point where major service or overhaul is required. Key points to consider:

- Use only genuine OEM or manufacturer-approved parts. A field article noted: "Do not assume that the local repair vendor has the expertise to bring the motor back up to the proper operating specifications."

- Re-evaluate service life in the context of hours, load cycles, environment (shock loads, mobile use).

- Document every service event: ensure the motor has a maintenance history, rebuild log, parts replaced.

Conclusion

In the world of hydraulics, the difference between a smooth-running system and constant downtime often comes down to how well the motor is installed and how diligently it is maintained. From ensuring a secure, vibration-free installation to maintaining fluid cleanliness, every step is crucial for maximizing the lifespan and performance of the hydraulic motor.

At Poocca, we understand that excellence begins before the machine even runs one hour. With over 20 years of industry experience and a vast product range covering gear pumps, piston pumps, vane pumps and motors, Poocca is your trusted partner in hydraulic power and reliability.

Whether you're looking for a high-torque axial piston motor or a rugged gear motor for mobile equipment, we provide one-stop hydraulic solutions, backed by strong technical support, quality control and global shipping.

By aligning proper installation practices, proactive maintenance regimes and smart motor selection, you can minimise unplanned outages, cut lifecycle costs and keep your equipment operating at peak efficiency. When you're ready, Poocca is ready-with the products, know-how and service to make your hydraulic system perform.

Ready to get started? Reach out to Poocca's technical team today for support on motor sizing, installation checklists or maintenance-kit options - and take the next step toward hydraulic reliability.

Five Quick FAQs

What size hydraulic motor do I need?

You should select one based on required torque, speed, system pressure and fluid flow - aligning with your application's duty, environment and load profile.

How often should filters and fluid be checked or changed?

It depends on operating conditions, but generally daily checks of fluid level and leaks, weekly/monthly inspection of filters, and quarterly/annual fluid-analysis and deeper inspection are recommended.

Why is alignment so critical during installation?

Because misalignment or side-loads on the shaft cause stress on bearings and internal components, leading to accelerated wear or failure.

What are early warning signs that a hydraulic motor needs attention?

Look out for unusual noise, increased vibration, abnormal temperature rise, leaks, or a drop in torque/speed.

Can I postpone a motor overhaul or replacement?

Only up to a point - when internal wear, performance drop or contamination trends are detected, delaying service can lead to sudden failure and greater cost. Proper logs and trend monitoring help plan timely overhaul.