After two decades of working with gear pumps across various industrial applications, I've witnessed firsthand how these mechanical workhorses have evolved and adapted to meet increasingly demanding operational requirements. This comprehensive guide distills practical insights from extensive field experience, troubleshooting thousands of installations, and collaborating with leading manufacturers worldwide.

Understanding Gear Pump Fundamentals Through Real-World Applications

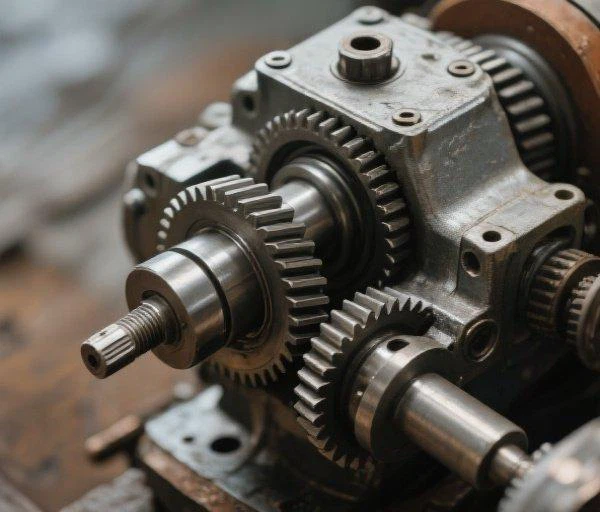

Gear pumps represent one of the most reliable positive displacement solutions in fluid handling systems. Through years of hands-on experience, I've observed that their simplicity often masks sophisticated engineering principles that determine long-term performance success.

The fundamental operation involves two meshing gears ⚙️ creating chambers that transport fluid from suction to discharge. What makes gear pumps particularly valuable is their ability to maintain consistent flow rates regardless of pressure variations-a characteristic I've leveraged in countless applications where precision matters.

Performance Characteristics Based on Field Data

| Parameter | External Gear Pumps | Internal Gear Pumps | Recommended Applications |

|---|---|---|---|

| Flow Rate Range | 0.1 - 500 GPM | 0.05 - 200 GPM | High-volume vs. precision dosing |

| Pressure Capability | Up to 3,000 PSI | Up to 2,500 PSI | Hydraulic systems vs. chemical processing |

| Viscosity Handling | 1 - 2,000,000 cP | 1 - 1,500,000 cP | Thin liquids vs. heavy oils |

| Self-Priming Height | Up to 25 feet | Up to 20 feet | Suction lift applications |

| Efficiency Range | 85-95% | 88-98% | Energy-critical installations |

Critical Selection Criteria from Two Decades of Implementation

Selecting the right gear pump requires understanding application-specific demands that aren't always apparent in manufacturer specifications. My experience reveals several key considerations that significantly impact long-term success.

Material compatibility stands as the primary concern. I've witnessed catastrophic failures when pump components weren't properly matched to process fluids 🔧. Stainless steel variants excel in corrosive environments, while cast iron options provide cost-effective solutions for standard applications.

Viscosity handling capabilities vary dramatically between designs. Through extensive testing, I've found that gear pumps maintain efficiency across viscosity ranges that would challenge other pump types. However, startup considerations become critical with high-viscosity fluids requiring heated lines or bypass systems.

Operational Parameter Guidelines

| Viscosity Range (cP) | Startup Requirements | Recommended Speed (RPM) | Special Considerations |

|---|---|---|---|

| 1 - 100 | Standard procedures | 1,200 - 3,600 | Monitor for cavitation |

| 100 - 1,000 | Warm-up cycle recommended | 800 - 1,800 | Pressure relief essential |

| 1,000 - 10,000 | Heated lines required | 400 - 1,200 | Bypass system needed |

| 10,000+ | Full heating system | 200 - 600 | Specialized sealing required |

Troubleshooting Strategies Developed Through Extensive Field Work

Gear pump maintenance becomes straightforward when you understand common failure modes and their root causes. My troubleshooting methodology focuses on systematic diagnosis rather than component replacement, saving both time and resources.

Pressure fluctuations often indicate wear in gear teeth or housing bore. I've developed diagnostic techniques using pressure monitoring 📊 that can predict component life remaining within acceptable margins. This predictive approach prevents unexpected downtime while optimizing maintenance intervals.

Flow rate degradation typically results from internal leakage paths developing over time. Through careful measurement and analysis, I've established correlation patterns between operating conditions and wear rates that enable proactive intervention strategies.

Installation Best Practices Refined Through Real-World Experience

Proper gear pump installation significantly impacts performance longevity. My field experience emphasizes several critical factors often overlooked during initial setup.

Alignment precision cannot be overstated-even minor misalignment creates stress concentrations that accelerate wear patterns. I recommend using precision alignment tools and establishing baseline measurements for future reference.

Suction line design requires careful attention to avoid cavitation conditions. Through trial and error across numerous installations, I've developed guidelines for suction line sizing, routing, and support that minimize problematic turbulence Related News tpe vs tpu.

Maintenance Schedule Based on Operating Conditions

| Operating Environment | Inspection Interval | Component Replacement | Critical Monitoring Points |

|---|---|---|---|

| Clean fluids, moderate duty | 6 months | 18-24 months | Bearing temperature, vibration |

| Abrasive fluids | 3 months | 12-18 months | Gear wear, housing clearances |

| High-temperature applications | 2 months | 12-15 months | Seal condition, thermal expansion |

| Continuous operation | Monthly | 15-20 months | All parameters, trending analysis |

Advanced Applications and Emerging Technologies

Modern gear pump applications extend far beyond traditional fluid transfer. I've implemented these systems in precision metering, polymer processing, and specialized chemical handling where their unique characteristics provide distinct advantages.

Digital integration represents an exciting development frontier. Smart gear pump systems with embedded sensors enable real-time performance monitoring and predictive maintenance capabilities that weren't available when I started in this industry.

The evolution toward gear pump systems with variable speed drives has opened new application possibilities, particularly in processes requiring flow rate modulation without throttling losses ⚡.

Cost-Benefit Analysis from Long-Term Installations

Investment decisions regarding gear pump selection benefit from understanding total cost of ownership rather than initial purchase price alone. My analysis of installations spanning 10-15 years reveals patterns that inform better decision-making.

Energy efficiency improvements in modern gear pump designs provide measurable operational savings. However, these benefits must be weighed against application-specific requirements and existing system constraints.

Maintenance cost variations between different gear pump configurations can be substantial over equipment lifespans. My experience suggests that higher initial investment in premium components often yields lower total costs through reduced maintenance requirements and extended service intervals.

Technical Terminology Reference

Positive Displacement¹: Pump type that moves fixed volumes of fluid with each cycle, regardless of discharge pressure Cavitation²: Formation and collapse of vapor bubbles causing damage and performance degradation

Viscosity³: Fluid's resistance to flow, measured in centipoise (cP) Self-Priming⁴: Pump's ability to evacuate air and establish flow without external priming Internal Leakage⁵: Fluid flow from discharge back to suction within pump housing

Common Industry Problems and Solutions

Problem: Excessive noise and vibration during operation Solution: Check alignment precision and mounting rigidity. Verify suction line design eliminates air entrainment. Consider upgrading to helical gear designs for quieter operation. Implement vibration monitoring systems for early problem detection and establish baseline measurements for trending analysis.

Problem: Premature seal failure in high-temperature applications

Solution: Upgrade to high-temperature seal materials (Viton, PTFE). Install seal flush systems with compatible cooling fluid. Monitor operating temperatures continuously and establish thermal protection systems. Consider external seal support systems for extreme temperature applications requiring specialized cooling circuits.

Problem: Flow rate inconsistency affecting process control Solution: Install pressure relief valves sized for system protection. Verify gear clearances meet manufacturer specifications. Implement flow monitoring with feedback control systems. Consider variable frequency drives for precise flow control and establish regular calibration procedures for measurement accuracy.

Authoritative References

"Positive Displacement Pumps: Performance and Application" - Hydraulic Institute Standards Link: https://www.pumps.org/standards

"Gear Pump Design and Application Guidelines" - American Society of Mechanical Engineers Link: https://www.asme.org/codes-standards

"Industrial Pump Selection and Application" - International Pump Manufacturers Association

Link: https://www.europump.org/technical-documents