Hydraulic motors are the silent workhorses in countless machines - from excavators and cranes to industrial presses and marine winches. They convert pressurized fluid into mechanical rotation. But among all the different types of hydraulic motors, which one is generally the most efficient? That's the central question of this article.

Before we dive into specific motor types, let's clarify what we mean by "efficiency." In everyday language, "efficient" just means "does more for less"- in hydraulics, that means converting more of the fluid's energy into usable mechanical power, with as little wasted heat, leakage, and friction as possible.

What "Efficiency" Means in Hydraulic Motors

In the context of hydraulic motors, we usually break efficiency down into two (or three) components:

Volumetric efficiency (η_v)

This measures how much of the theoretical fluid volume is actually used to produce motion, versus how much is wasted by internal leakage or slip.

ηv=actual flow delivered/theoretical flow

If your motor theoretically should displace 100 cm³ per revolution, but due to leaks you only get 90 cm³, your volumetric efficiency is 90%.

Leakage can increase with wear, poor seals, excessive clearances, or high pressure.

Mechanical (or hydraulic) efficiency (η_m)

This accounts for energy lost to friction, bearing drag, fluid shear, sealing friction, etc. Even if fluid is flowing perfectly, pushing parts against each other loses power.

It is often expressed as:

ηm=theoretical torque (or mechanical output)/actual torque input (or losses included)

A value of 1.0 (100 %) is unrealistic, because friction always exists.

Overall efficiency (η_o)

This is the "bottom line" - how much of the input power ends up as useful mechanical work. It's essentially the product of volumetric and mechanical efficiencies:

ηo=ηv×ηm.

For example, if volumetric = 0.90 and mechanical = 0.92, then overall = 0.90 × 0.92 = 0.828, or 82.8 %.

In practice, when someone says "this motor is 90 % efficient," they usually mean the overall efficiency under certain operating conditions.

Main Types of Hydraulic Motors

Here's a quick qualitative summary of how the types tend to compare (in terms of efficiency potential):

| Motor Type | Volumetric Efficiency Potential | Mechanical Loss Risk | Overall Efficiency Potential | Best Use / Strengths |

|---|---|---|---|---|

| Gear | Low to moderate | Moderate | Moderate | Robust, simple, low cost |

| Vane | Moderate | Moderate | Moderate to good | Smooth, balance point between cost & performance |

| Axial Piston | High | Moderate to low (if well designed) | High | Flexible, good speed/torque range |

| Radial Piston | High | Moderate | Very high under favorable conditions | High torque at low speeds |

| Gerotor / Orbital | Low to moderate | Moderate | Moderate | Compact, simple, cost-sensitive applications |

Which Type Tends to Be Most Efficient - Theory & Evidence

Now we get to the heart of the matter: when all is said and done, which type of hydraulic motor tends to be most efficient in real systems? To answer that, we'll look at theoretical advantages, empirical evidence, and trade-offs.

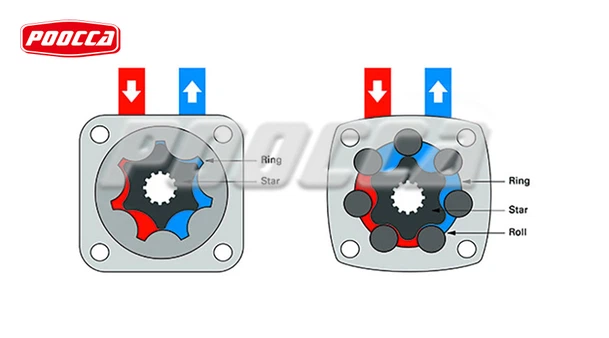

Theoretical Edge of Radial Piston Motors

Many hydraulic specialists view radial piston motors as efficiency champions, especially in certain operating regimes (low speed, high torque). Here's why:

- Superior volumetric efficiency

The radial layout can better isolate leakage paths. Because pistons act radially, sealing surfaces can be tightly controlled and balanced, reducing internal leakage.

- Strong low‐speed, high‐torque performance

Radial piston motors are often used as LSHT (Low Speed High Torque) motors. They can deliver significant torque directly without needing a gear reduction stage, thus avoiding losses in extra gearing.

Some radial types can even run at extremely low "creep" speeds while maintaining nearly constant output torque.

- Less mechanical loss potential (in ideal design)

Because the radial pistons push outward/inward against a cam or eccentric ring, force paths can be well balanced. If the design is precise, friction and bearing losses can be minimized.

- Long service life and stable performance

Though manufacturing is more demanding, in many applications radial piston motors maintain high efficiency over time better than more leakage-prone designs.

Drawback to acknowledge: radial piston motors often have limited top speed. At high RPMs, dynamic effects, inertia, and leakage start to hurt efficiency.

Because of these features, when you see hydraulics literature or industrial motor catalogs, radial piston motors are frequently the go-to choice when efficiency and torque density are among the top design goals.

The Case for Axial Piston Motors: Strong Contender

Radial piston motors may often win on "pure efficiency in ideal regime," but axial piston motors are not far behind - and in many practical systems they may be the most efficient choice, given their broader operating range.

Good efficiency across speed & load ranges

Axial piston motors (swashplate or bent axis) tend to perform well, especially in medium to high speed ranges. Their design enables decent volumetric sealing and relatively manageable mechanical losses.

In fact, in many systems that require variation of displacement (variable displacement axial motors), the ability to tailor flow/torque matches your demand well, mitigating wasted energy.

Better high-speed capability

Unlike radial pistons, axial designs tend to be more forgiving at higher RPM. They can maintain better balance and avoid some of the inertial stresses that radial types suffer at high speed.

More common & cost-efficient in many cases

Because axial piston motors have been more widely used and engineered, there's more maturity in design, parts, control of tolerances, servicing, and cost scaling. That means you can often get high efficiency in "normal" operating ranges more affordably than pushing a complex radial motor to do everything.

Thus in many practical systems - especially where speed variation, medium-to-high RPM, or cost vs. performance tradeoffs matter - axial piston motors often end up being the "best efficient" choice for that system's envelope.

Here is a clear English table comparing typical overall efficiencies of different types of hydraulic motors / pumps. (Note: these are rough ranges from textbooks and engineering lectures - actual values depend heavily on design, operating conditions, wear, fluid quality, etc.)

| Motor / Pump Type | Typical Overall Efficiency Range | Strengths / Efficiency Advantages | Main Efficiency Challenges |

|---|---|---|---|

| Gear (spur / external / internal gear) | ~ 70 % – 75 % mechanicalengineering120. | Simple construction, robust, tolerant of contamination | High internal leakage between gear teeth and housing, sliding friction, lower pressure performance |

| Vane | ~ 75 % – 85 % mechanicalengineering120. | Better sealing than gear, smoother flow, moderate cost | Friction of sliding vanes, wear over time, sensitivity to fluid cleanliness |

| Piston (axial / radial) | ~ 85 % – 95 % mechanicalengineering120.files. | High potential volumetric and mechanical efficiency; good sealing, low leakage in well-made designs | More complex, high precision required, sensitive to wear and maintenance, performance drops outside ideal regime |

Start with Your System Requirements (Don't Begin with Motor Type)

Before looking at motor catalogs, gather key data and specifications of your system. Many guides agree that selection must flow from the load back to the motor.

Ask:

What is the required torque (start, continuous, stall)?

What speed / RPM range must the motor cover?

What flow rate (volume of hydraulic fluid) is available or allowable?

What system pressure will the motor see (max, continuous)?

Will the motor have to operate at low speed with heavy load?

How variable is the load (steady, cyclic, shock loads)?

What are constraints on size, weight, cost, maintenance, environment?

What about fluid properties, contamination level, temperature, etc.?

Do you have to fit into an existing hydraulic circuit (fixed pump, piping)?

These parameters define the "design envelope" your motor must survive in.

Use a Trade-Off Framework: Efficiency vs. Practical Constraints

Once you know your system envelope, you can rank trade-offs. Here's a decision framework:

| Decision Factor | How It Affects Efficiency / Motor Choice | What to Watch For |

|---|---|---|

| Low-speed, high-torque requirement | Favors radial piston or LSHT designs (less or no need for gearing) | If your motor can supply torque directly, you avoid extra gearbox losses |

| Broad speed range or variable load | Favors axial piston (especially variable displacement) | The ability to adjust displacement helps avoid wasted flow |

| Maximum required RPM | If your system needs high speed, radial designs may struggle | Axial designs often better at sustaining higher RPM |

| Pressure environment | High pressure tends to increase leakage losses | Choose motor types with better sealing and tolerances |

| Cost / complexity / maintenance | Less complex types (gear, vane) may be cheaper but lower peak efficiency | Sometimes a simpler motor with lower "realized" losses is better overall |

| Available flow and pump size | If flow is limited, you may need a motor with smaller displacement or variable displacement | Mismatch can lead to under-utilized or overworked motor |

| Environmental / contamination constraints | Some designs are more sensitive to cleanliness and fluid quality | In dirty environments, a more robust but slightly less efficient motor may be safer |

| Installation & piping | Losses in piping reduce what the motor "sees" | Minimize piping losses, avoid sharp bends, undersized hoses |

Use this framework to evaluate candidate motor types in the context of your system, rather than assuming one type is always best.

Conclusion

When someone asks, "What type of hydraulic motor is generally most efficient?", the simplest-but most nuanced-answer is:

Radial piston motors often hold the title in ideal conditions (especially in low-speed, high-torque regimes), thanks to their tight sealing, excellent volumetric performance, and ability to deliver torque without additional gearbox loss.

But in real systems, axial piston motors frequently rival them-especially in moderate to high speeds, variable loads, and cost/maintenance trade-offs. Gear and vane motors usually fall behind in peak efficiency, but may win when cost, robustness, or simplicity matter most.

Here's a quick "giveaway checklist" you can reference when deciding:

- Know your operating envelope (speed, torque, pressure, load variability).

- Consider the net system efficiency, not just motor efficiency in isolation (include piping, valves, gearboxes).

- Check real efficiency curves / manufacturer data under your expected operating points.

- Factor in cost, maintenance, robustness, fluid quality, and installation constraints.

- Don't oversize - a motor running far below its design point often loses efficiency.

A Word About Poocca (Your Hydraulic Partner)

If you're sourcing hydraulic motors or designing hydraulic systems, one name you might come across is Poocca. Poocca Hydraulic, based in Shenzhen, China, is a full-service hydraulic supplier offering gear pumps, vane pumps, piston (axial) pumps, motors, valves, and related accessories.

Because Poocca covers a wide product range, from gear to piston motors, they can help you explore multiple motor options for your specific efficiency tradeoffs-rather than locking you into just one style. If you reach out to them with your torque, speed, pressure, and application requirements, they may assist in selecting a well-matched motor that balances efficiency, cost, and durability.

FAQ (Frequently Asked Questions)

Here are five common questions readers might ask, with concise answers:

| Question | Answer |

|---|---|

| 1. Which hydraulic motor type is usually the most efficient? | In ideal conditions, radial piston motors often lead in efficiency, especially at low speed and high torque, thanks to tight sealing and low leakage. But axial piston motors can be nearly as efficient in many real systems, and sometimes end up being a better system-level choice due to their broader speed range and flexibility. |

| 2. Why can't any hydraulic motor reach 100% efficiency? | Several unavoidable losses exist: internal fluid leakage (reducing volumetric efficiency), friction between moving parts (reducing mechanical efficiency), pressure drops in the system, and heat losses. The overall efficiency is always less than the product of the ideal flows and torque conversions. |

| 3. How does operating speed or load affect which motor is "most efficient"? | Efficiency is not constant. At low speeds, leakage losses become more significant, favoring motors with minimal leakage (e.g. radial piston). At high speeds, friction, inertia, and dynamic effects grow, favoring designs that handle those stresses well (often axial piston). Also, mismatch between load demands and motor displacement can push efficiency down. |

| 4. If I already have a hydraulic pump and piping, does that change the "best" motor choice? | Yes. The motor's efficiency must be considered in the context of the entire system. Losses in piping, valves, fittings, and any gearbox will reduce the "net" efficiency you realize. Sometimes a slightly less efficient motor that better matches your existing circuit yields higher overall system efficiency. |

| 5. What practical steps can I take to preserve or boost the efficiency of the motor I choose? | Good question. Some key steps include: keeping the hydraulic fluid clean, selecting proper viscosity and temperature control; ensuring tight tolerances and good seal condition; matching motor displacement to expected load (avoiding oversizing); optimizing the hydraulic circuit (shorter lines, fewer bends, proper sizing); and regular inspection and maintenance to prevent wear and leakage growth. |